As the “online quality inspector” in strip production, the strip surface inspection system has become standard equipment on many strip production lines.However, due to the complex environment and high strip speed at the exit of cold tandem mills, the application of surface quality inspection systems has long been regarded as “the toughest nut to crack”.Relying on its core technologies and practical experience in metal surface inspection, IET has successfully delivered high-speed strip surface inspection systems at the exit of cold tandem mills for POSCO and Lianyuan Steel, greatly reducing batch defects such as mill roll marks, improving detection efficiency and ensuring better quality control.Recently, IET has once again won the contract for the mill exit surface inspection system for the 6-high cold tandem silicon steel mill project of Lianyuan Steel, empowering the surface quality control of high-end cold-rolled silicon steel products!We strive to set a new model for surface quality inspection at the exit of cold tandem mills!

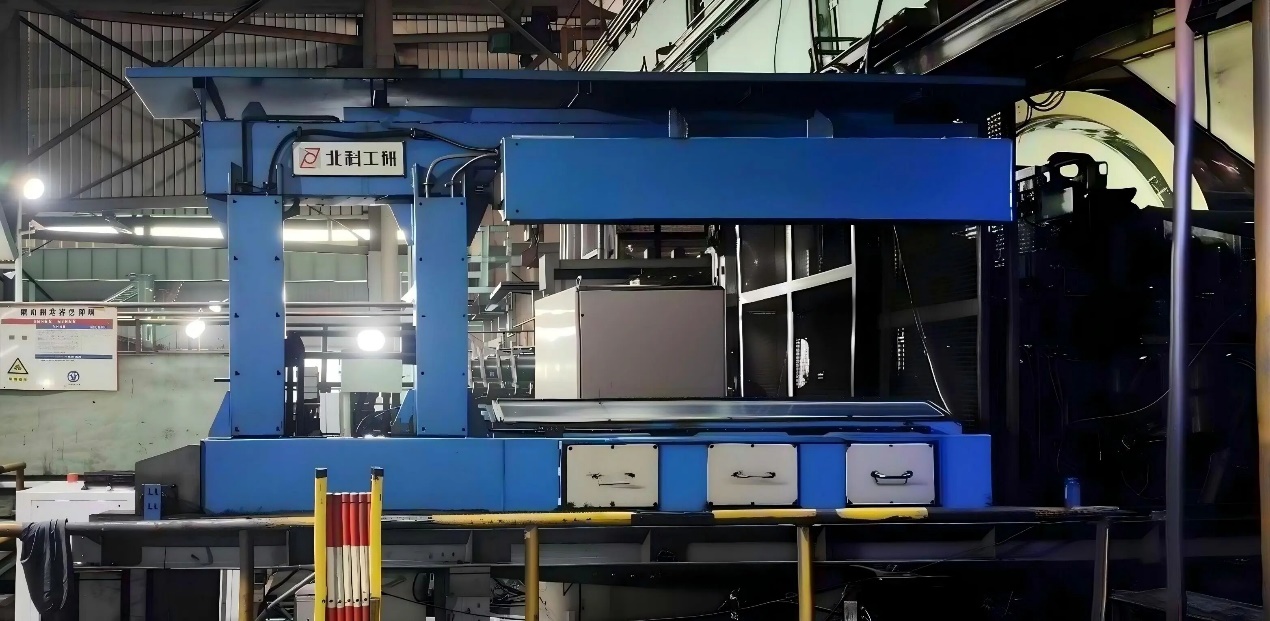

01 Narrow Space+High Speed: Capturing Every Inch of High-Speed Strip Surface at the Cold Mill Exit

The harsh environment at the cold tandem mill exit leads to common pain points: “cannot capture” and “cannot image clearly”.IET’s intelligent inspection team adopted a “modular+embedded” layout, integrating a special high-brightness optical imaging system and protective device into a narrow space of only 300 mm to adapt to the mill exit environment.The system realizes precise tracking imaging of “strip moving, camera following”, delivering clear images even at a speed of 1800 m/min.

02 From Post Inspection to Real-Time Prevention: Being the Quality Gatekeeper in Narrow Spaces

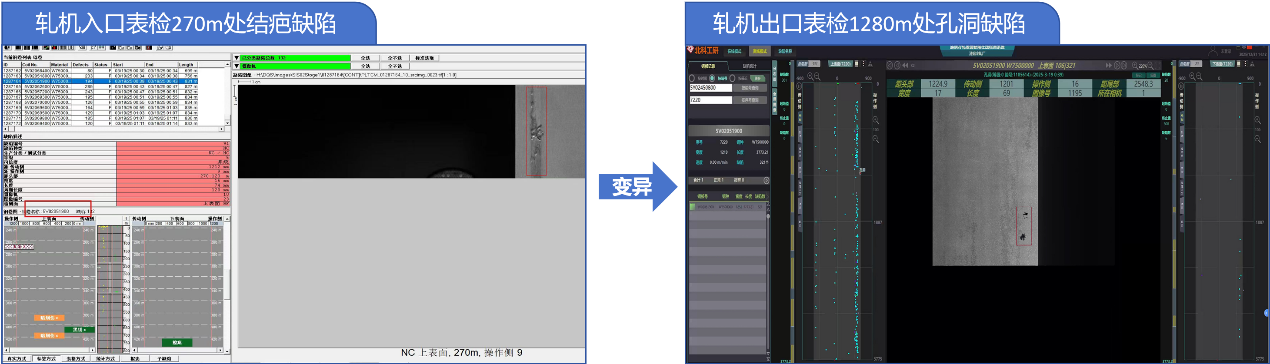

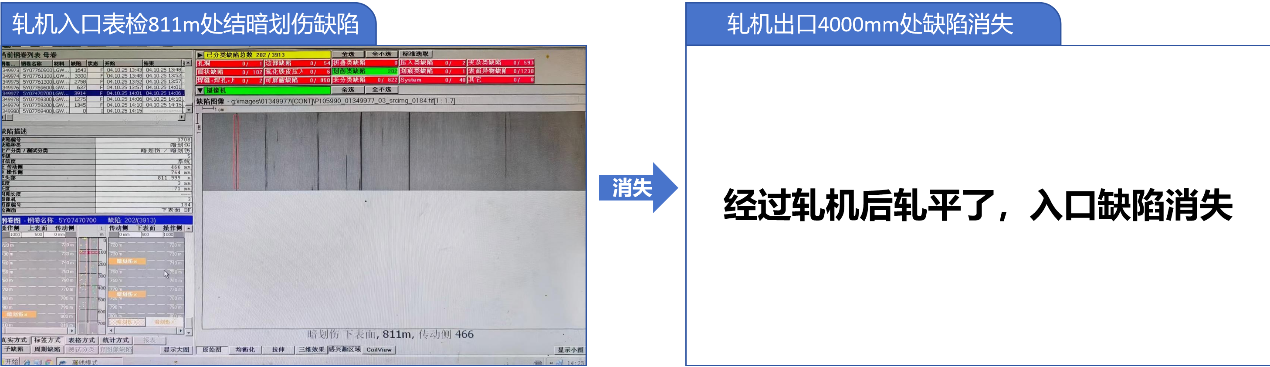

Surface inspection systems are usually installed at the entrance of pickling tandem mills.However, defects detected at the entrance may “evolve” or “disappear” after rolling.Without online inspection at the mill exit, many defects would flow to the next process or even to customers.

With IET’s surface inspection system installed at the pickling tandem mill exit, complete data traceability before and after rolling is established for both “defect evolution” and “defect disappearance”, acting as a reliable quality gatekeeper for the mill area.

03 Empowered by IETSI‑HSTG‑V1.3 Defect Detection Large Model: Data Creates Value

Another difficulty in high-speed cold-rolled strip defect detection is the lack of defect samples.In the traditional mode, customers usually have only a few thousand defect images with scattered types, making AI models “unable to learn” and “unable to recognize accurately”.IEThas developed the IETSI‑HSTG‑V1.3 general large model dedicated to strip defect detection, combined with a few-shot fine-tuning strategy, based on its massive accumulated defect data map.

This solution solves the sample shortage problem and achieves a defect detection rate above 95% upon commissioning.

04 “Online Learning” for Continuous Optimization

Through an online learning mechanism, the system automatically optimizes recognition rules.After receiving new defect samples, it uses a multi-model framework to enhance single-category defect detection and recognition, becoming “smarter” over time to meet the highest on-site application standards and empower customers’ quality control.