Controlled rolling and cooling of steel plates and strips are important methods to save energy, control the mechanical properties of steel plates, produce special-purpose steel plates and to improve the competitiveness of products in modern steel rolling. We are committed to original innovation and independent integrated development of controlled rolling and cooling of steel plates and strips, and have developed the first intermediate and differential temperature rolling cooling equipment and the first standardized medium and heavy plate controlled cooling equipment in China. We have realized the independent integration and innovation in controlled rolling and cooling equipment and rolling quenching machine for steel plates and strips. The developed cooling equipment covers all types of cooling equipment applied in the rolling production line for steel plates and strips in China. We are now the first scientific research institution with application achievements for all controlled steel plate and strip cooling equipment in China, which is indicative of our leading position in the research field of controlled rolling and cooling of steel plates and strips in China.

The core devices in the controlled cooling equipment are the coolers on the upper and lower surfaces of the steel plate or strip. High cooling speed and uniformity are critical issues in this process. We have successfully developed an ultra-dense cooler with independent intellectual property rights through laboratory research and engineering practice, based on the research on the heat transfer mechanism and internal evolution mechanism of steel plate/strip cooling, and have reached globally advanced levels in terms of cooling capacity, uniformity and other parameters. The equipment can realize high-speed and high uniformity cooling along the length, width and thickness of the steel plate or strip, to produce products with excellent flatness and performance.

We have won several invention patents in the field of controlled rolling and cooling of steel plates and strips, such as “A medium-thick plate online quenching inclined jet cooler” and “A tape-line pre-straightening accelerated online cooling method”. We have also won several ministerial and provincial-level scientific and technological awards in Fujian Province, Jiangsu Province, from China Iron and Steel Industry Association, etc. The equipment is being applied in over 50 production lines in Ansteel, WISCO, HBIS, SD Steel and other manufacturers, and has led to immense economic benefits. The controlled cooling equipment applied in WISCO has been successfully used to develop the Q460E/Z35 steel plates that were used in the Bird’s Nest in Beijing, covering the gap in China in terms of product availability. It has also made immense contributions to the structure adjustment of plate/strip products as well as improved the added value and product competitiveness.

The typical applications are:

S/N | Manufacturer | Width of Rolling Machine (mm) | Production Year |

1. | Ansteel - heavy plate | 4,200 | 2000 |

2. | Wusteel - heavy plate | 4,200 | 2002 |

3. | WISCO - rolled plate | 2,800 | 2003 |

4. | NISCO - coiled sheet (modified) | 3,500 | 2007 |

5. | XISC - medium plate | 4,100 | 2008 |

6. | Sansteel - medium plate (intercooler unit) | 3,000 | 2009 |

7. | Xingjiang Bayi Iron & Steel (ultra-dense quick cooling) | 3,500 | 2010 |

8. | Wenfeng Iron & Steel | 4,300 | 2010 |

9. | CISC - heavy plate (intercooler unit) | 4,100 | 2011 |

10. | LISCO - medium plate (ultra-dense quick cooling, modified) | 3,000 | 2013 |

11. | JN Steel - standardized cooling unit | 4,300 | 2014 |

12. | Nanyang Hanye - quenching machine | 3,800 | 2008-2015 |

13. | Han-Steel - 2250 hot continuous rolling (quick cooling, modified) | 2,250 | 2012、2016 |

14. | Nanyang Hanye - medium plate (ultra-dense quick cooling, modified) | 3,500 | 2017 |

15. | Laiwu Steel - 1500 hot continuous rolling (quick cooling, modified) | 1,500 | 2017 |

16. | XinSteel - 1580 hot continuous rolling (quick cooling, modified) | 1,580 | 2017 |

17. | LISCO - medium-plate quenching machine (spare parts) | 3,000 | 2018 |

18. | Nanyang Hanye - medium and heavy plate (intercooler unit) | 3500、3800 3,500 and 3,800 | 2018 |

19. | Anyang Iron & Steel - 1780 hot continuous rolling (integrated quick cooling, modified) | 1,780 | 2018 |

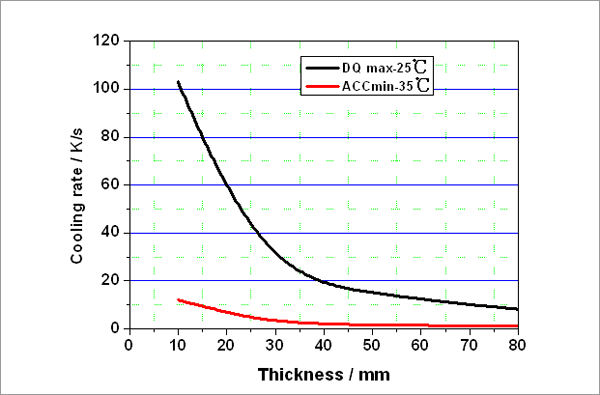

DQ and ACC of ultra-dense cooler under different water temperatures

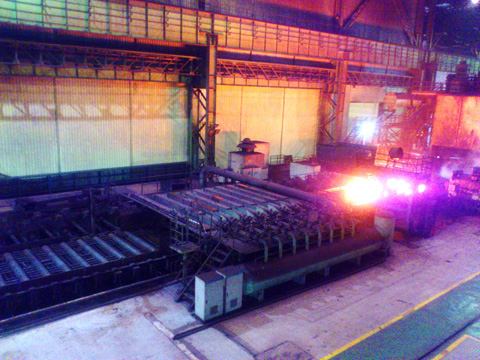

Rolling controlled cooling unit – ultra-dense upper spraying cooler at Xinjiang Bayi Iron & Steel 3,500 mm medium and heavy plate production line (2009)

Intercooler unit of cogging and finishing mills of CISC 4,100 mm medium and heavy plate production line (2013)

Standardized furnace controlled cooling unit for the heat treatment line of JN Steel 4,300 mm wide and heavy plate (2014)

Rolling quenching machine for the heat treatment production line of Nanyang Hanye 3,800 mm (2015)

Ultra-dense cooler on quick cooling unit of the continuous heat rolling production line of Han-Steel - 2,250 mm (2016)