The Institute’s research and development team is focused on studying the atmospheric environmental pollution problem that China urgently needs to solve. It relies on the scientific research platform of “Beijing Key Laboratory of Energy Saving and Emission Reduction of Metallurgical Industry”, “Beijing Key Laboratory of Industrial Typical Pollutant Resource Treatment”, and other platforms, to carry out research and analysis on typical gas pollutant emission characteristics, metallurgical industry flue gas pollutant control and synergistic purification, special external field synergistic catalytic purification, environmental functional materials and purification equipment development and engineering applications. In particular, the Institute has rich research experience in low-temperature denitration catalysts, SO2 adsorbents, organic sulfur hydrolysis catalysts, malodorous gas purification materials and VOC purification materials, and has achieved remarkable success in related scientific research and engineering.

The main research directions are: (1) flue gas desulfurization and denitration technology in metallurgical industry; (2) VOC treatment technology; (3) synergistic purification technology of flue gas and other pollutants; and (4) key technologies and equipment for catalyst/adsorbent regeneration. Furthermore, the R&D team has full-process service capability from technology, to material-design/equipment and engineering. The R&D team is focused on providing flue gas desulfurization, denitration, dust removal treatment technology, environmental engineering design and spare parts supply for the metallurgical industry, to meet ultra-low emission requirements.

Complete solution 1: integrated medium-high-temperature flue gas selective catalytic reduction denitration + desulfurization and dust removal (dense-phase dry tower process)

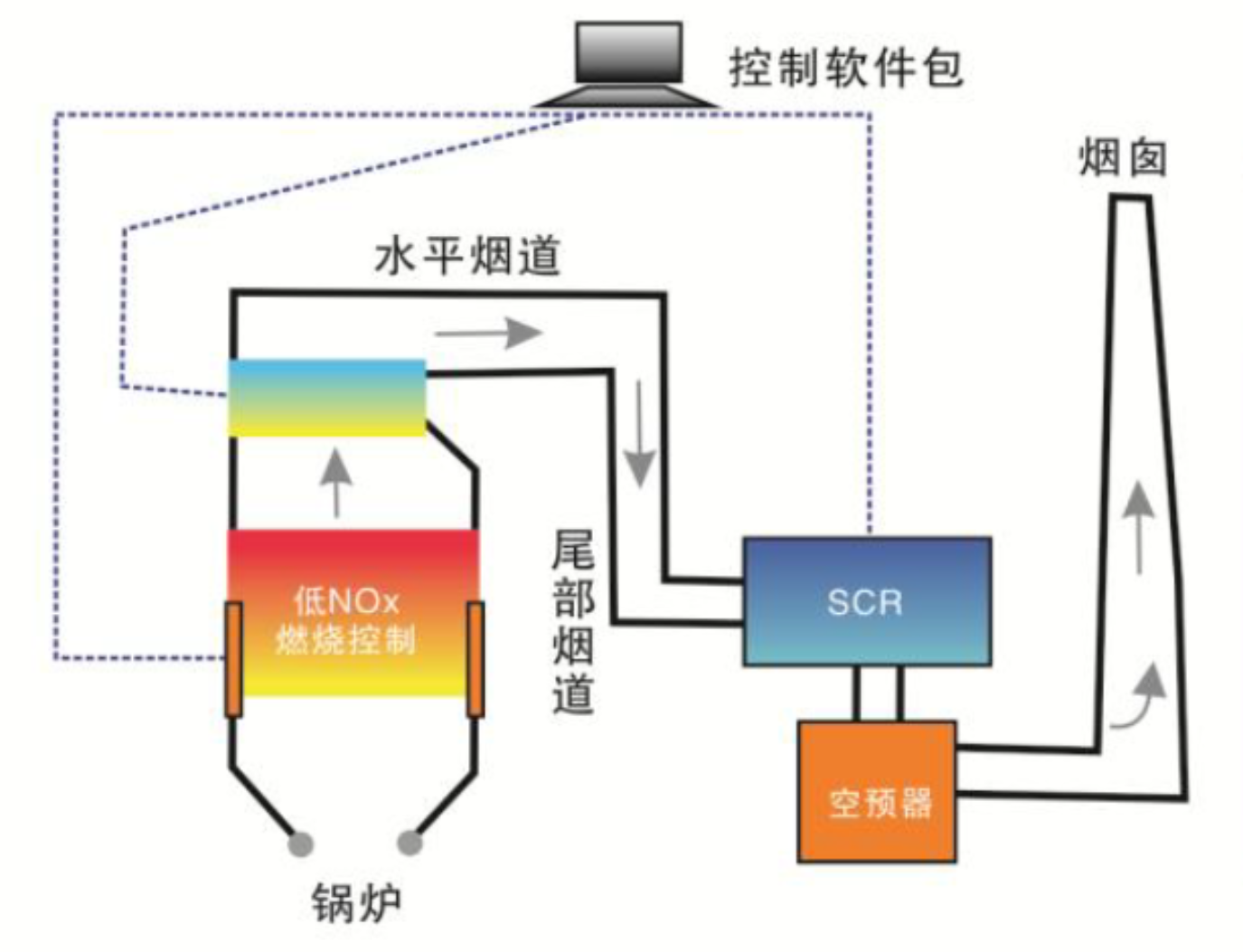

Currently, the Selective Catalytic Reduction (SCR) denitration technology is the most widely used flue gas denitration technology worldwide. The technology refers to the use of reducing agents (such as NH3, liquid ammonia and urea) to “selectively” react with NOx in flue gas, to produce non-toxic and non-polluting N2 and H2O under the action of the catalyst, to reduce the emission of NOx. The Institute is committed to the development and application of advanced denitration technologies. At present, it has mastered core technologies such as SCR jet grid design, flow field CFD simulation, reactor modeling and catalyst modular production.

Fig. 1 Schematic diagram of SCR denitration process

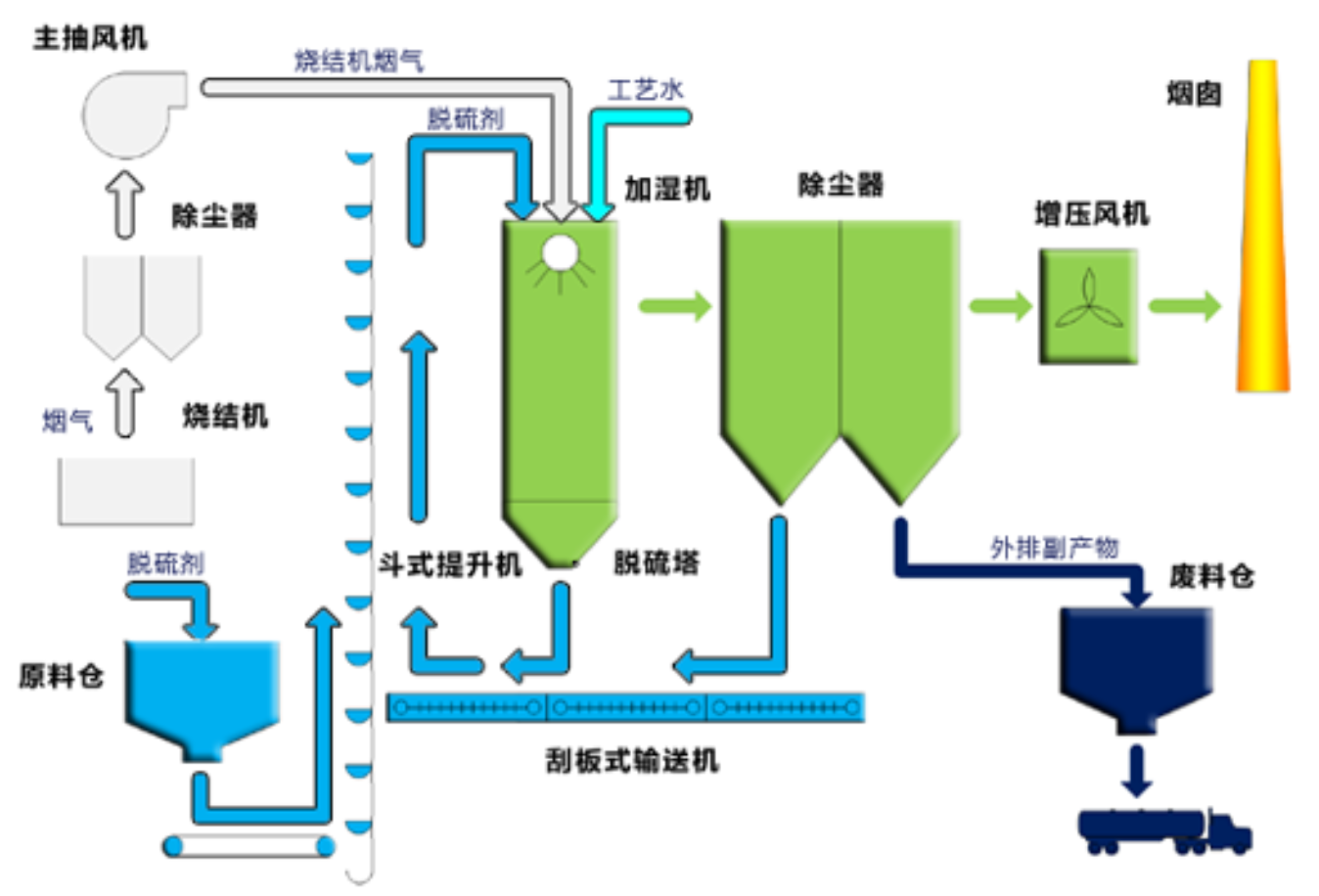

In the dense-phase dry tower process (flue gas desulfurization technology), the flue gas enters the tower from the upper part of the dense-phase tower, mixes with the humidified desulfurizing agent at the top of the tower, and is dispersed and mixed by the chain stirrer in the tower, to accelerate the reaction between the desulfurizing agent and SO2 in the flue gas, which generates solid CaSO4 particles. A large amount of flue gas containing particles is discharged from the lower outlet of the dense-phase tower, and enters the dust remover, where the gas and solids are separates, and the purified flue gas is discharged through the dust remover to the chimney. The solid particles at the bottom re-enter the dense-phase tower and continue to participate in the reaction, and a small amount of reacted desulfurizing agent is discharged into the waste bin, which is a complete system cycle.

Fig. 2 Dense-phase dry tower process flow diagram

Fig. 3 Comprehensive coke oven flue gas denitration, desulfurization and dust removal project at Han-Steel (140,000 m3/h)

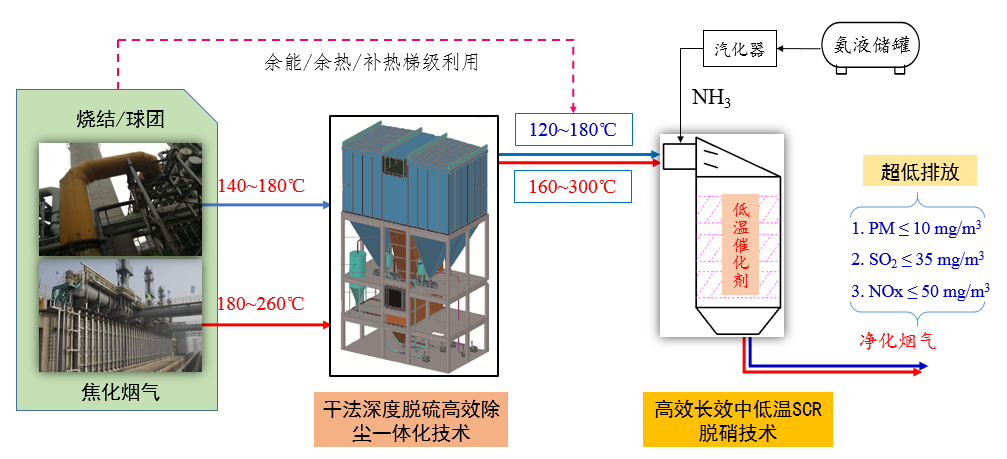

Complete solution 2: integrated deep desulfurization and dust removal of medium-low temperature flue gas (dry process) + efficient medium-low temperature SCR denitration

Fig. 4 Comprehensive synergistic medium-low temperature flue gas purification technology

With the prevailing ultra-low emission policy of the government, sodium bicarbonate (NaHCO3) can be used as a high-efficiency desulfurizing agent, and has a favorable removal effect on most acid gases, with the removal rate reaching: SO2 > 99%, SO3 > 99%, and Hg > 95%. The biggest advantage of adopting the dry powder spray method is that multiple substances can be removed simultaneously in one device. In addition, compared with wet and spray methods: (1) the dry powder spray method is simpler with less equipment, lower cost and lower maintenance requirement; and (2) the basic principle of spray drying desulfurization technology can be used for dry powder spray desulfurization technology, and there is no requirement for water consumption. As sodium bicarbonate is injected into the reactor, the thermal decomposition reaction starts at 60°C and an activation reaction occurs. When the temperature is raised from 160°C to 220°C, the reaction rate can be almost doubled.

The dry desulfurization technology is applicable to a wide range of temperature (160°C~220°C), and the degree of reduction in smoke temperature is small. The desulfurization efficiency of the dry powder spray method is as high as 99%, and it has a favorable removal effect with respect to most acid gases. It is more suitable for high-efficiency desulfurization of medium-low temperature flue gas such as steel sintering/pelletizing (smoke temperature: 120°C~180°C) and coke oven (smoke temperature: 200°C~280°C), and combined with high-efficiency bag integration technology, it can achieve comprehensive desulfurization and dust removal. Furthermore, the smoke temperature after desulfurization and dust removal matches the subsequent low-temperature SCR denitration technology (150°C and above).

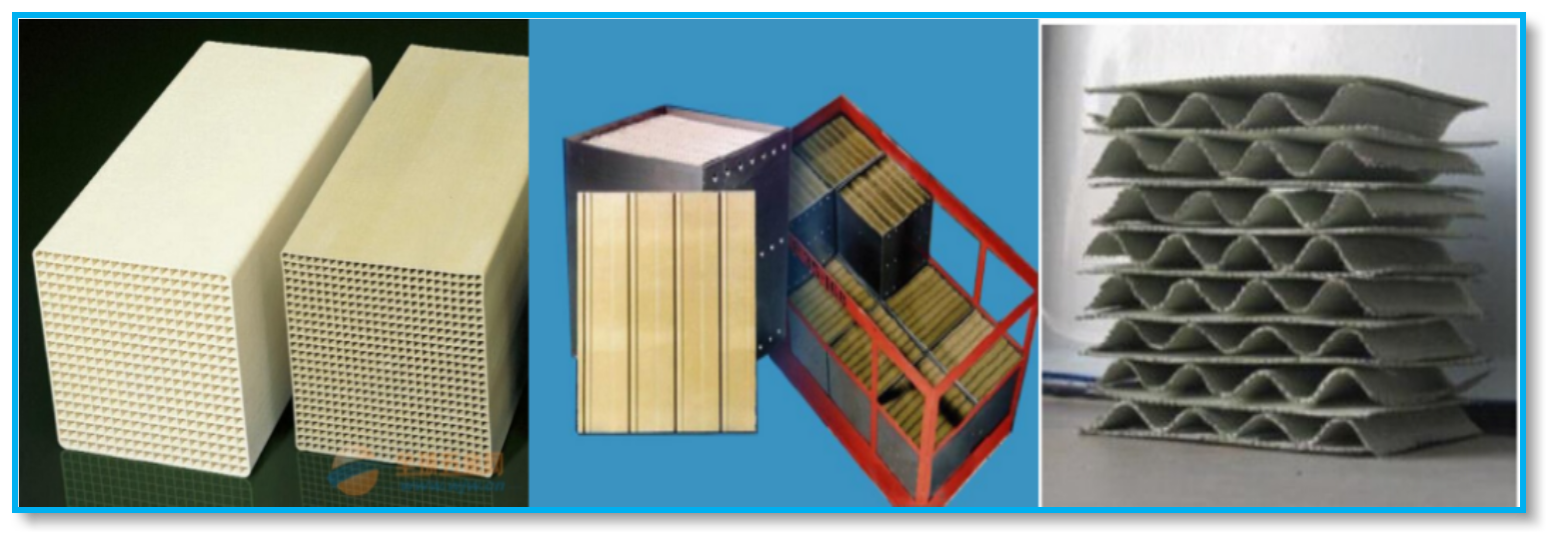

Fig. 5 Medium-low temperature SCR catalyst type denitration

Medium-low temperature SCR denitration technology: Since the reactor is arranged after the dust remover and the flue gas desulfurization system, there is no need to modify the boiler body. Moreover, the reaction tower for low-temperature denitration has a small volume, is simple to install, occupies limited floor space, and has greatly reduced overall cost. After dust removal and desulfurization, the content of pollutants such as fly ash, SO2, alkali/alkali earth metal oxides and their salts as well as heavy metals in the flue gas are relatively low, reducing the possibility of pollution and poisoning of the catalyst to some extent. This prolongs the service life of the catalyst, while avoiding clogging and corrosion of the reactor and other devices by the fly ash, and reduces the maintenance costs.

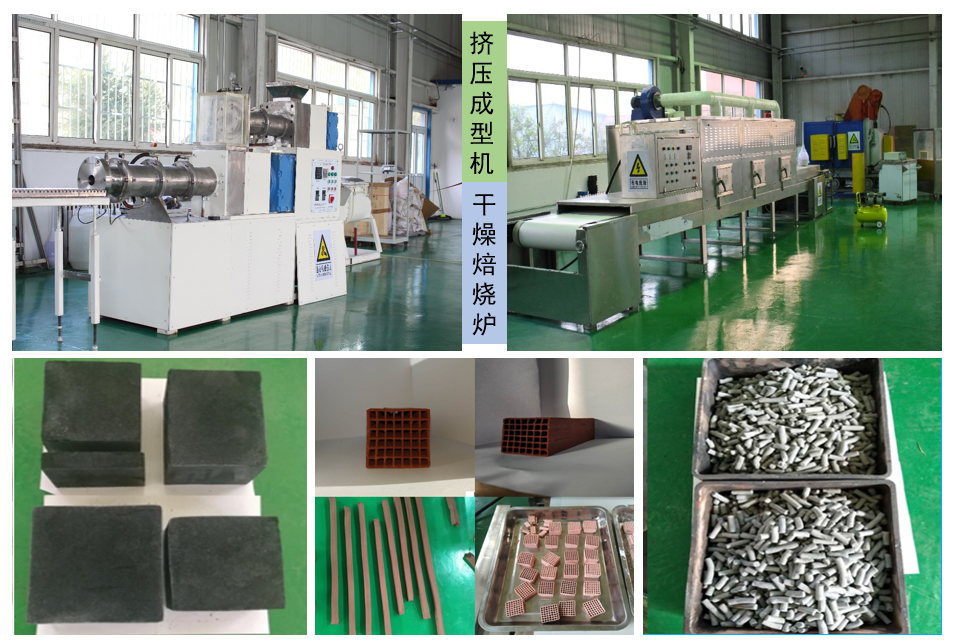

Fig. 6 R&D Team: SCR catalyst production equipment and product samples